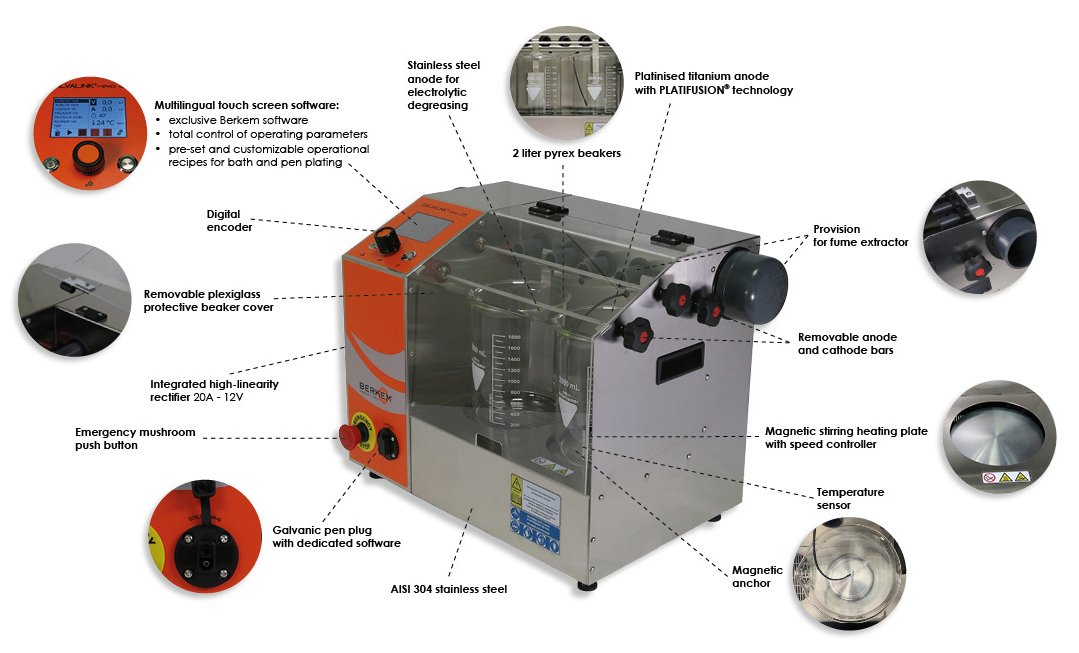

GALVALINK-evo 2B , 2-liter base unit, is the new galvanic machine with an innovative design, high performance, and maximum versatility.

It is the ideal solution for those seeking efficiency and precision in the galvanic process, both in bath and pen modes.

Made entirely of AISI 304 stainless steel, it ensures resistance and durability even under intensive usage conditions.

Its compact size and modular design make it perfect for both small artisanal workshops and larger, scalable production environments.

Total control over the working parameters, via preset and customizable operating recipes, ensures optimal result repeatability and eliminates errors, offering a significant competitive advantage over standard machinery available on the market.

The interaction between the touch screen and digital encoder, with intuitive controls, makes managing parameters extremely simple, even for less experienced users. The integrated high-linearity rectifier allows for more uniform, burn-free deposits, improving quality and reducing production waste

Total control of working parameters through preset operating recipes for each Berkem process and customizable for use with any professional-use galvanic solution available on the market

All electrical and electronic components are placed in protected areas to prevent infiltration and ensure stability and safety during use

Attention to energy efficiency allows for reduced consumption without compromising quality

The integrated plug for the galvanic pen with a dedicated software offers maximum application flexibility

The fully visible Pyrex beakers enable real-time monitoring of every phase of the process. The removable protective cover ensures operation

The modular design allows for maximum adaptability to various application types

The construction in AISI 304 stainless steel ensures not only superior mechanical and chemical resistance but also ease of cleaning and durability

The software is specifically designed for optimizing galvanic processes, for bath and pen, and allows for future updates

Provision for connection to the factory’s suction or to the optional dedicated suction unit

STANDARD EQUIPMENT

– Integrated high-linearity rectifier | 20A – 12V

– Multilingual touch screen software

– Digital encoder

– Magnetic stirring heating plate with speed controller

– Magnetic anchor

– 2 liter pyrex beakers

– Removable anode and cathode bars

– Steel anode for use in electrolytic degreasing solutions

– Platinised titanium anode with PLATIFUSION® technology for use with any precious metal-based electroplating solution

– Removable plexiglass protective beaker cover

– Emergency mushroom push button

– Galvanic pen plug

OPTIONAL EQUIPMENT

– Dedicated galvanic pen cable

– Integrated fume extractor motor

– Connection cables for satellite unit